MicroStep's modular fiber laser product line allows creation of customized systems that range from simple machines to complex cutting centers with different work area sizes, technologies and automation options. Equipped with state-of-the-art laser sources and cutting heads, efficient fume extraction and safety cabins, MSF machines are delivered as turnkey solutions with a variety of functions that meet the ever growing requirements of our end users.

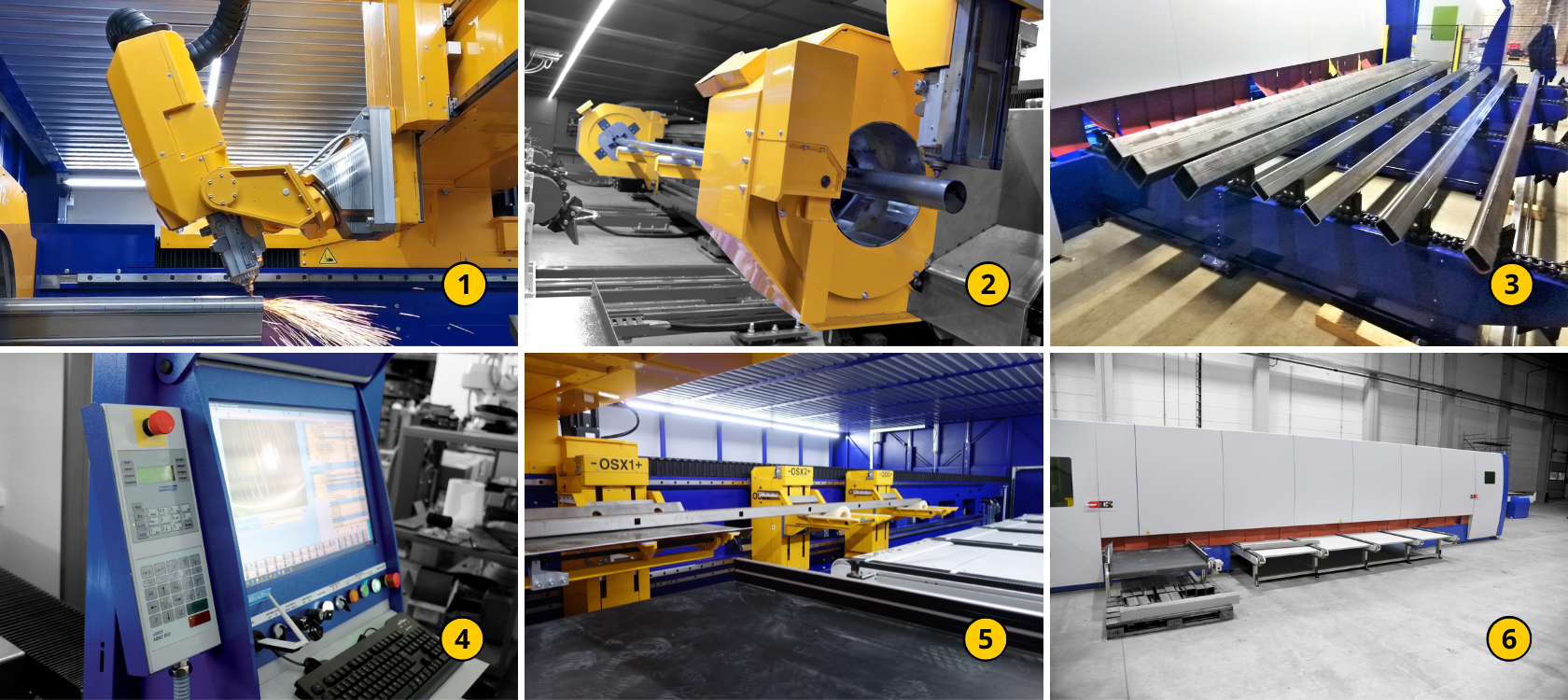

❶ -

Fully automated MicroStep fiber laser line: a 4 x 2 m MSF Pro bevel cutting machine with 8 kW beam shaping fiber laser, a hydraulic shuttle table and a 10-storey storage tower with automatic loading/unloading. The line can be operated in auto-mode by MicroStep's CyberFab Manager: based on the task list, the machine calls for the corresponding material from the tower and after the cutting is finished, requests the loader to unload the cut parts. The system constantly monitors its 8 loading and 2 unloading cassettes and in case the unloading positions in the tower are full, it asks the operator to take the parts out. Place of installation: France.

First in the line,

MSF Compact, is a plug-and-produce solution for smaller workshops offered in three standard sizes with work areas of 1 x 2 m, 1.25 x 2.5 m and 1.5 x 3 m. Equipped with laser sources up to 8 kW, the machine is an ideal solution for accurate and reliable 2D cutting up to 15 mm thick plates when a small machine footprint is required. MSF Compact has a single cutting grate that is pulled out of the cabin to the front.

To save valuable production time by allowing simultaneous cutting and loading/unloading, machines with shuttle tables are the setup to go. The basic version, MSF Cut, is dedicated to straight cutting of plates with a single cutting head. MSF Cut is delivered in three sizes – 3 x 1.5 m, 4 x 2 m and 6 x 2 m.

❷ -

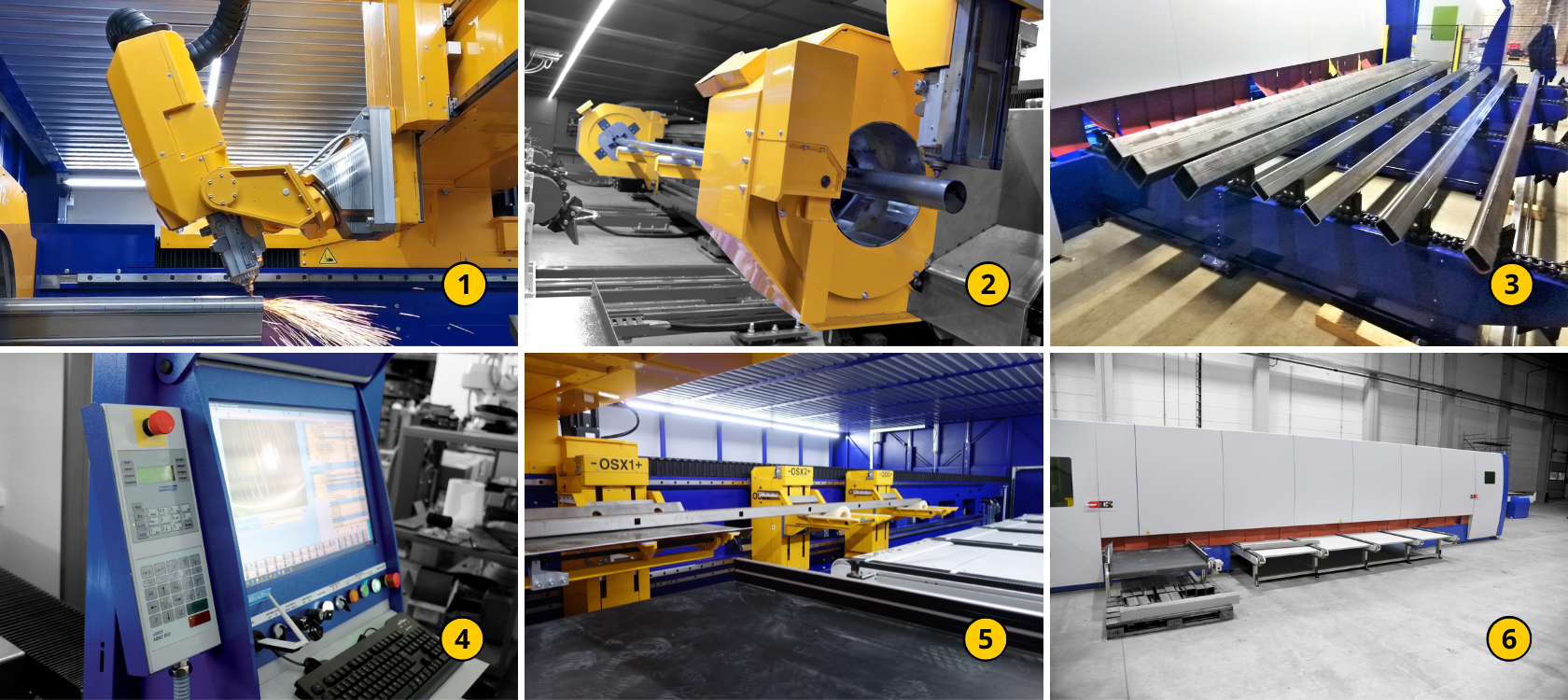

Large-scale fiber laser bevel machine MSF Pro with work area 16 x 3 m and a 15 kW laser source, installed at a Dutch customer.The multifunctional MSF Pro seriesWhen looking beyond straight-forward laser cutting, the high-precision all-rounder

MSF Pro offers true multifunctionality: bevel cutting, marking, drilling and a handful of automation options. With shuttle tables up to 16 x 3 m ❷, the series provides exceptional metal processing capabilities such as chamfering of long parts with variable bevels, inkjet marking or tapping.

MSF Pro machines allow for combination of multiple cutting heads and also a combination of different technologies in one gantry ❻ that can be switched automatically within a single cutting plan. To accentuate efficiency, the machines come with automatic laser heads and gas consoles, automatic nozzle cleaning, height control calibration, as well as an option of automatic nozzle change ❹.

❹ -

Automatic nozzle changer is important equipment for automation.❻ -

14 m long multifunctional MSF Pro machine with laser beveling, additional beveling and inkjet marking features.MSF Max seriesOriginally launched for large-scale cutting tasks, the

MSF Max series can be delivered with overall table dimensions as large as 50 x 6 m. It is dedicated for custom applications, e.g. in the shipbuilding sector, or simply when some particularly wide work areas are needed. MSF Max can be equipped with one or two bevel heads and a drilling tool station up to Ø 30 mm.

The machine offers several setups of cutting tables and safety cabins: a movable, and optionally even a motorically retractable cabin ❺ that completely covers the work area, or a smaller light-weight cabin that encapsulates just the gantry with cutting heads. It can have a shuttle table, a shuttle loop system with rotating pallets or a standard fume extraction table with a vibration conveyor for waste disposal.

❺ -

MSF Max with mobile retractable cabin provides great flexibility of work area size.Laser bevel cutting: direct and additional bevelingMSF machines provide beveling capabilities with up to 45° angles that range from small contours to long variable bevels. Whether it is direct beveling or complex beveled edges achieved with ABP® process – with dozens of laser heads installed over the last few years, MicroStep has established laser bevel cutting as an efficient, uncomplicated and reliable process that aims to be commonly used for weld preparation. All laser bevel heads are calibrated via MicroStep's industry-leading auto-calibration system ACTG®.

❸ -

Combined MSF Pro machine for bevel cutting of plates up to 6 x 2 m and pipes up to 6 m length and Ø 300 mm diameter installed in Germany. Pipes and hollow sections are loaded manually from the side through the sliding side panels. The machine has a 6 kW laser source with beam shaping technology.Pipes and profilesBesides flat sheets, MSF Pro machines can be combined with equipment for cutting pipes up to Ø 200 mm, Ø 300 mm (or even Ø 500 mm) and hollow sections up to 280 x 280 mm. The pipe cutting area is placed inside the cabin next to the cutting table. Pipe handling is ensured through a sliding side panel of the safety cabin ❸.

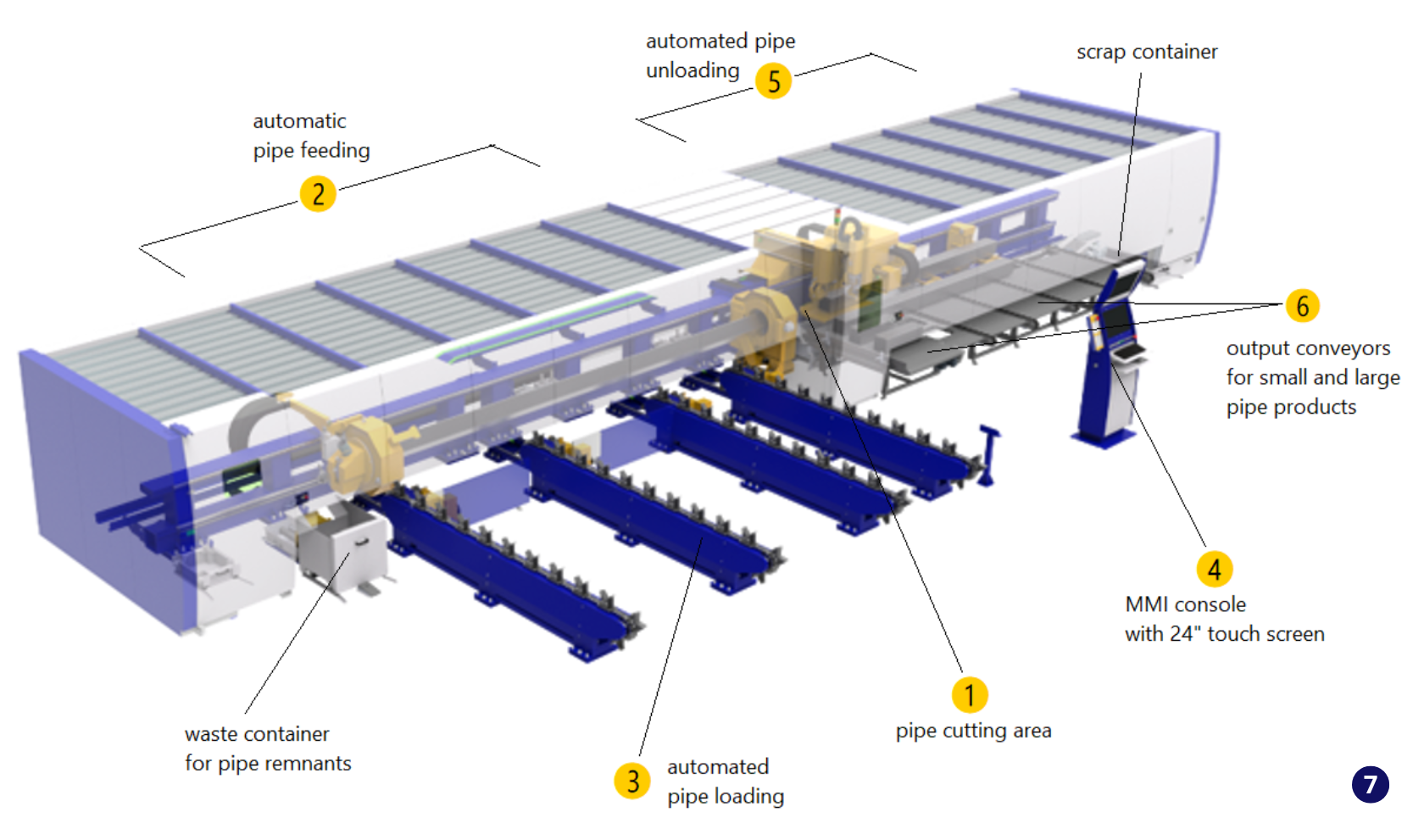

Cutting of pipes and profiles up to Ø 200 mm can be also fully automatic, with a transversal loading conveyor on the input, automatic feeding of pipes into the cutting area, and two transversal conveyors on the output for small and big parts. Both manual and automatic pipe cutting functions are available also as standalone cutting machines – the

MSF Pipe series ❼.

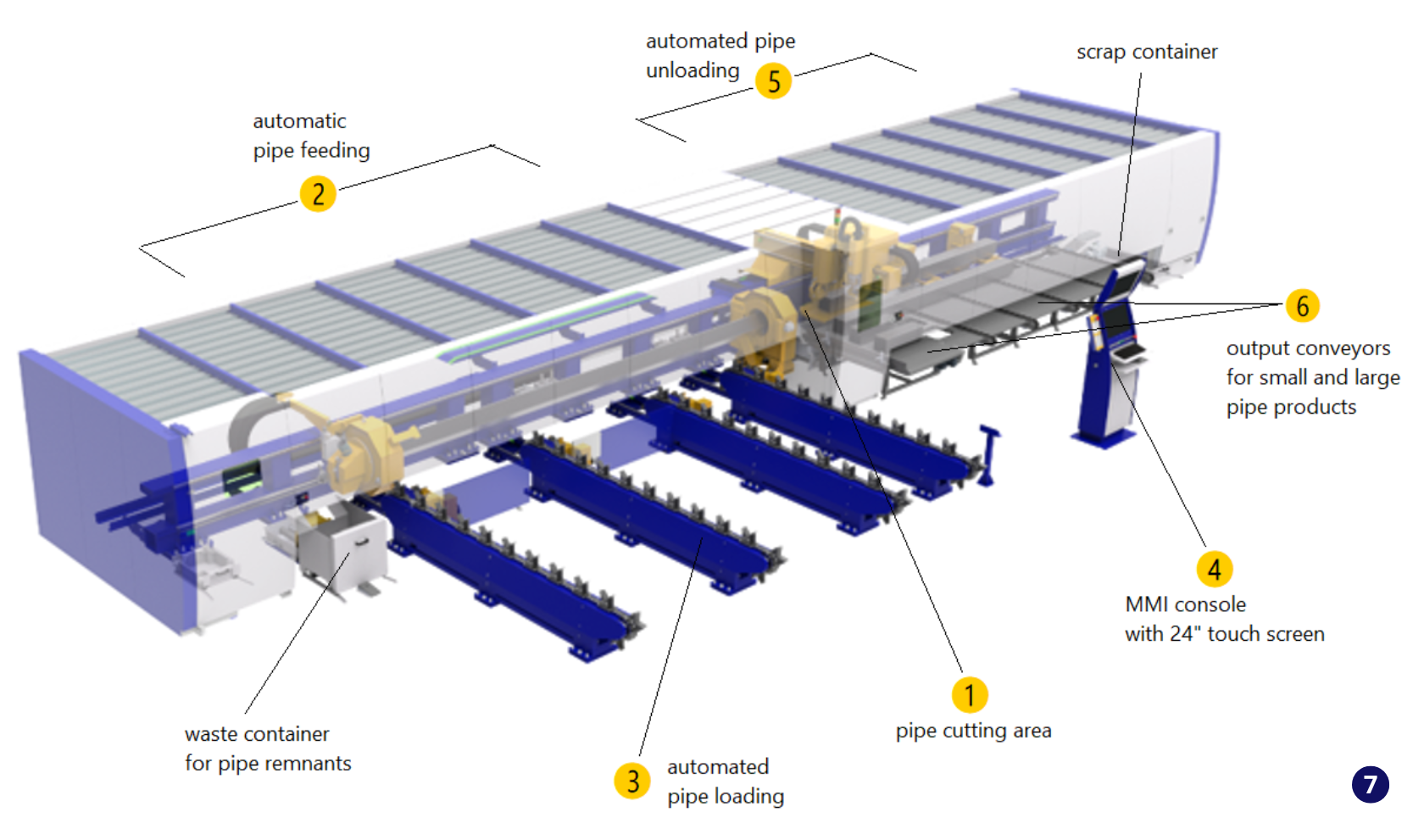

❼ -

7 Automated pipe cutting machine MSF Pipe designed for 2D or 3D cutting of round pipes up to 6 m length and diameter Ø 200 mm as well as for tubes of rectangular and other cross-sections. The machine features a laser scanner that is used to determine the real shape of pipes to be cut to ensure accurate cutting results. Material handling automationAutomating the handling of material is a logical requirement for many laser cutting applications. With

MSLoad,

MSTower ❶,

MSLoop and

MSSort, MicroStep offers a full suite of material loading, unloading, sorting and tower storage options (see also p. 12, 13 and EXTRA). All MicroStep laser automation solutions have a fair degree of customization with respect to customers' workflow and can be integrated with smart factory solutions.

EXTRA:Laser automation with three work positionsThe modular concept of laser cutting machinery that has the basic automation element – a pallet changer – already built-in by default, naturally encourages further automation enhancement. An example of such customization is a MSF Pro + MSLoad setup with an extended shuttle table that has three interchangeable pallets, delivered to an Italian steel service center. Having an extra position with the size of work area allows to separate the loading and unloading process and achieve higher throughput: all three operations – loading, cutting and unloading – can run simultaneously.

Moreover, the rather larger work area of this machine – 6 x 3 m – is designed for placing up to four 3 x 1.5 m sheets on each pallet which means that the workplace can be fully loaded with twelve 3 x 1.5 m sheets that can be processed fully automatically. An option of deactivating the fork unloader gives the customer a possibility to run the system in a loop – e.g. run laser marking on all three grates automatically overnight and during the day shift proceed with cutting.

Left: Unloading area of the middle pallet with MSLoad system, with a stockpile of unloaded orders in the front.

Left: Unloading area of the middle pallet with MSLoad system, with a stockpile of unloaded orders in the front.

Right: Simultaneous cutting, loading and unloading monitored from the operator console.

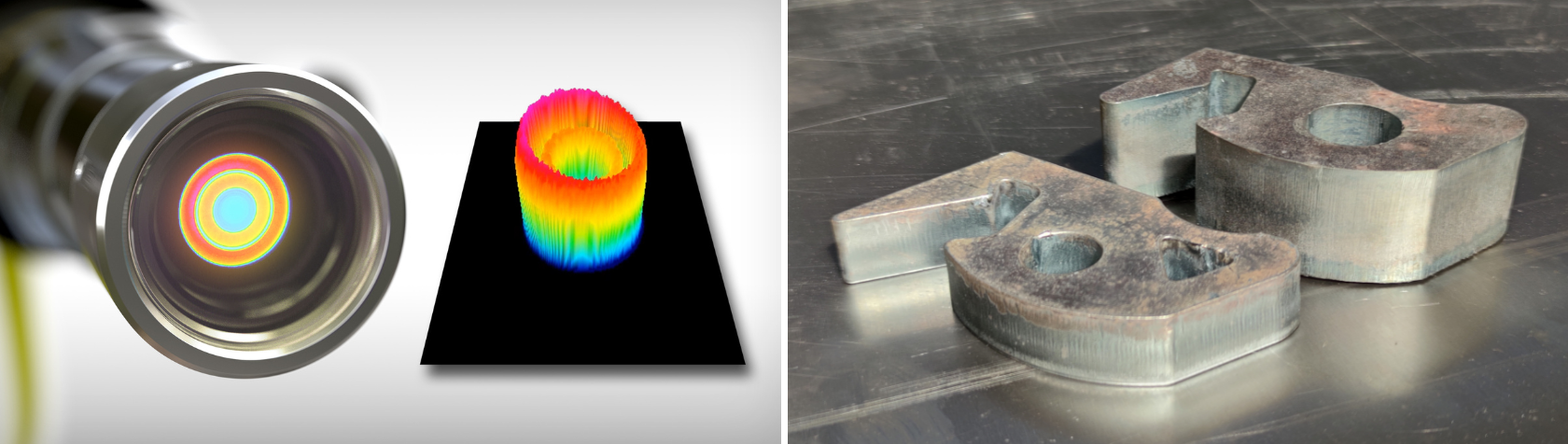

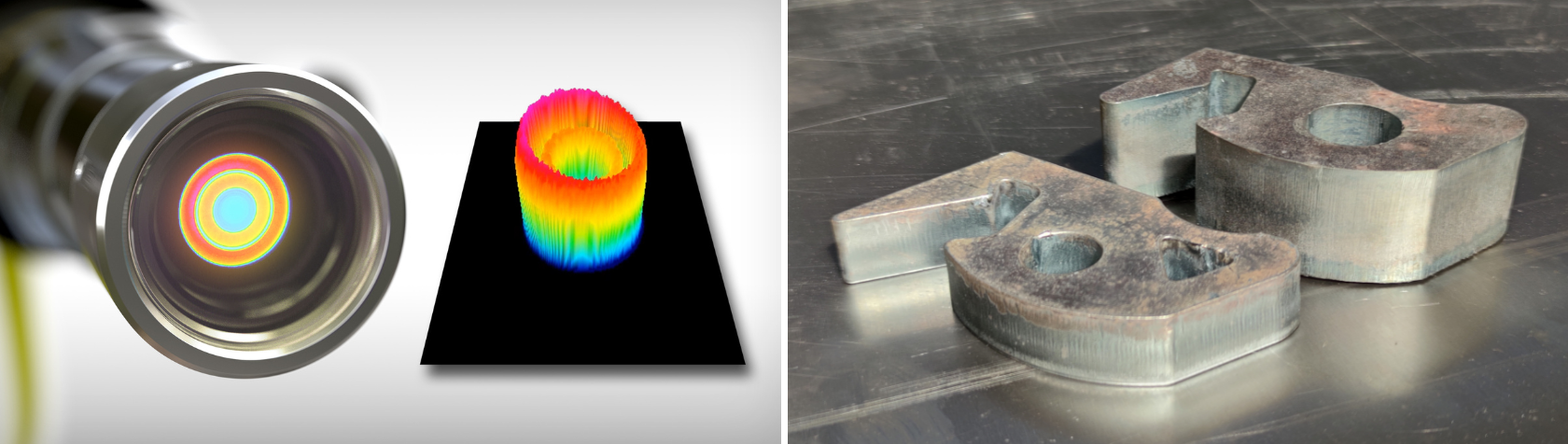

Optimal cutting results thanks to beam shaping

Beam shaping technology makes it possible to change and optimize shape, size and power density concentration of a fiber laser beam – in other words, to use the optimal fiber mode for your cutting task. It can provide a beam with a very small diameter, with a heat profile that is peaking in the center of the beam – but also a wide “donut”-shaped beam for achieving wider kerf.

This approach allows to reach highest speeds and performance on thin materials while cutting thicker materials with high quality, minimum dross and a 100% part drop-off. Integrated in all MicroStep fiber laser machines.