Located in the far south of Hungary, Faddikorr has been manufacturing top quality stainless steel tanks, pressure vessels and other equipment for food industry for more than 20 years now. In the beginning, there were only 4 people, but today “The Faddi Family” consists of more than 90 highly qualified and committed employees. What gives Faddikorr the edge over its competitors is the ability to meet all the special requirements of their clients while still attaining the highest quality possible. 3D plasma cutter DRM equipped with a pantographic plasma rotator capable of tilting up to 120˚ designed solely for cutting of domes up to Ø 3,500 mm

3D plasma cutter DRM equipped with a pantographic plasma rotator capable of tilting up to 120˚ designed solely for cutting of domes up to Ø 3,500 mmWhen it comes to pressure vessels, the most difficult and tedious task has always been tank ends and their machining. Cutting all the required openings into a tank end used to take a very long time, between half and one and a half day depending on the number and sizes of holes necessary for the specific pressure vessel. The purchase of a CNC plasma cutting machine from MicroStep has been a radical change in this matter. Cutting, which used to take a few skilled workers a day, now takes one hour and all the work can be done by a single machine operator. This was the main reason for purchase of the plasma dome cutting machine according to the owner of Faddikorr, Mr. János Faddi: “We decided to buy the machine in order to reduce the cost of human labor. The drawing and cutting of a tank end used to take sometimes more than a day. Thanks to the new machine, this time has been significantly reduced.”

With high quality in mind, Faddikorr opted for two CNC cutters from MicroStep: a fiber laser machine MSF Pro with a straight tool station with a work area of 6,000 x 2,000 mm, and a sturdy 3D plasma cutter DRM equipped with a pantographic plasma rotator capable of tilting up to 120˚ and with a Z-axis stroke of 1,500 mm, designed solely for cutting of domes up to Ø 3,500 mm. The integrated 3D scanner scans the dome’s surface to adjust the cutting program according to real dome dimensions.

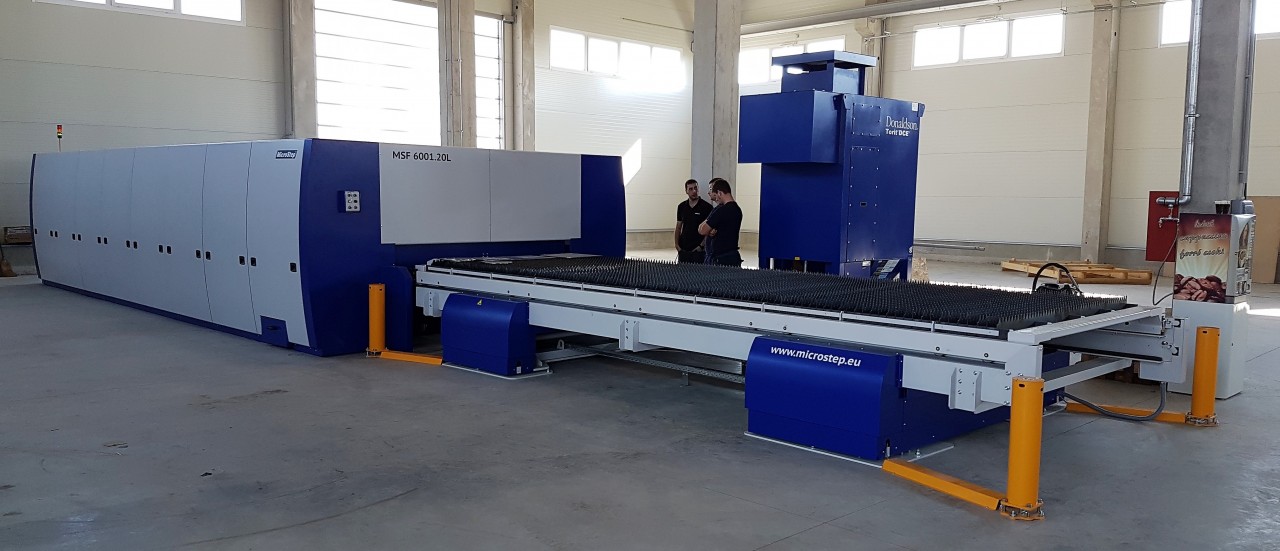

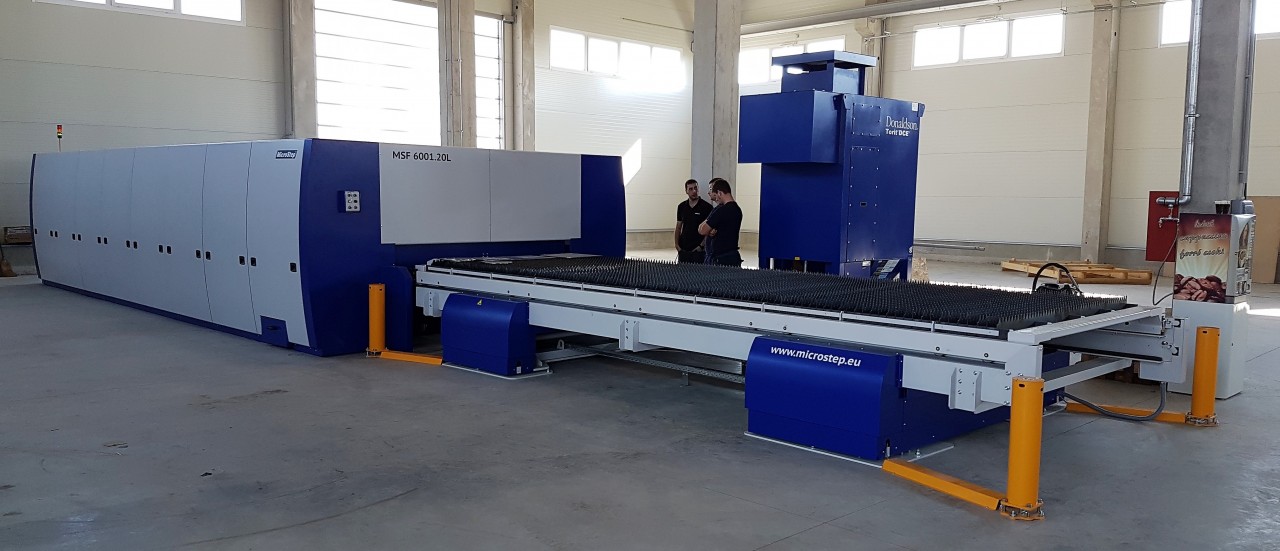

MSF Pro fiber laser cutting machine with a straight tool station and working area 6,000 x 2,000 mm

MSF Pro fiber laser cutting machine with a straight tool station and working area 6,000 x 2,000 mm In other words, local deformations of dome surface or an incorrectly placed, tilted dome are no longer a problem. Advanced cutting requirements such as various welding preparations – V-, A-, Y-, X- or K-cuts –are easy to handle thanks to the machine’s flexibility, its user-friendly interface and the easy way of working with 3D solid models in MicroStep’s 3D CAM software mCAM. For simpler tasks, like pipe-dome intersections, the machine also offers simple macros with functionalities like welding preparation generation or marking generation. The accuracy and long-term stability of 3D cutting is achieved thanks to MicroStep’s ACTG® system (Auto-calibration of tool geometry), which is able to calibrate the entire system within 5 minutes, making the former man-assisted, hours-long, manual geometry setup process basically obsolete.

“We produce our own conical tank ends out of sheet metal. The best way to cut openings in these is to do it before the sheets are bent into the cone shape. However, many times we do not know where the holes are going to be until the very last moment. Our MicroStep DRM dome cutting machine gives us the option to cut the openings into already formed tank ends, making our work much easier.”