Too many expensive laser parts that had to be purchased, a plasma cutting system that could not sufficiently cover all tasks at hand: Metallbau Pfister AG was looking for a compact laser cutting machine that does not require too much space but does not compromise on precision and speed. In the end, they found exactly what they were looking for: MSF Compact from MicroStep met all their requirements. “The laser system runs like clockwork. It's a great machine that fits perfectly into our limited space,” says Managing Director Curdin Pfister after several months of its operation.

The MSF Compact from MicroStep installed at Metallbau Pfister AG is a compact 2D cutting machine with a working area of 3 000 x 1 500 mm and has been in operation for ten hours a day.

Metallbau Pfister AG is only a few minutes’ drive away from the luxurious holiday resort of St. Moritz in the Engadine region of Switzerland. A wide range of customer groups from different industries trust the company's expertise and quality. “We are very flexible and broadly based. Customers often come to the office only with an idea. We try to meet their wishes with our knowledge,” says Mr. Pfister. More than 30 employees of the Swiss company offer a wide range of services - projects, buildings and products related to metal structures, locksmith work, as well as engineering services and ironwork.

Powerful fiber laser working 10 hours a dayThe MSF Compact from MicroStep installed at Metallbau Pfister AG is a compact 2D cutting machine with a working area of 3 000 x 1 500 mm and has been in operation for ten hours a day. “The laser system runs like a clockwork, which is very, very gratifying. It is the perfect machine for our limited space,” says Mr. Pfister.

“The laser system runs like a clockwork, which is very, very gratifying. It is the perfect machine for our limited space,” says Managing Director Curdin Pfister.

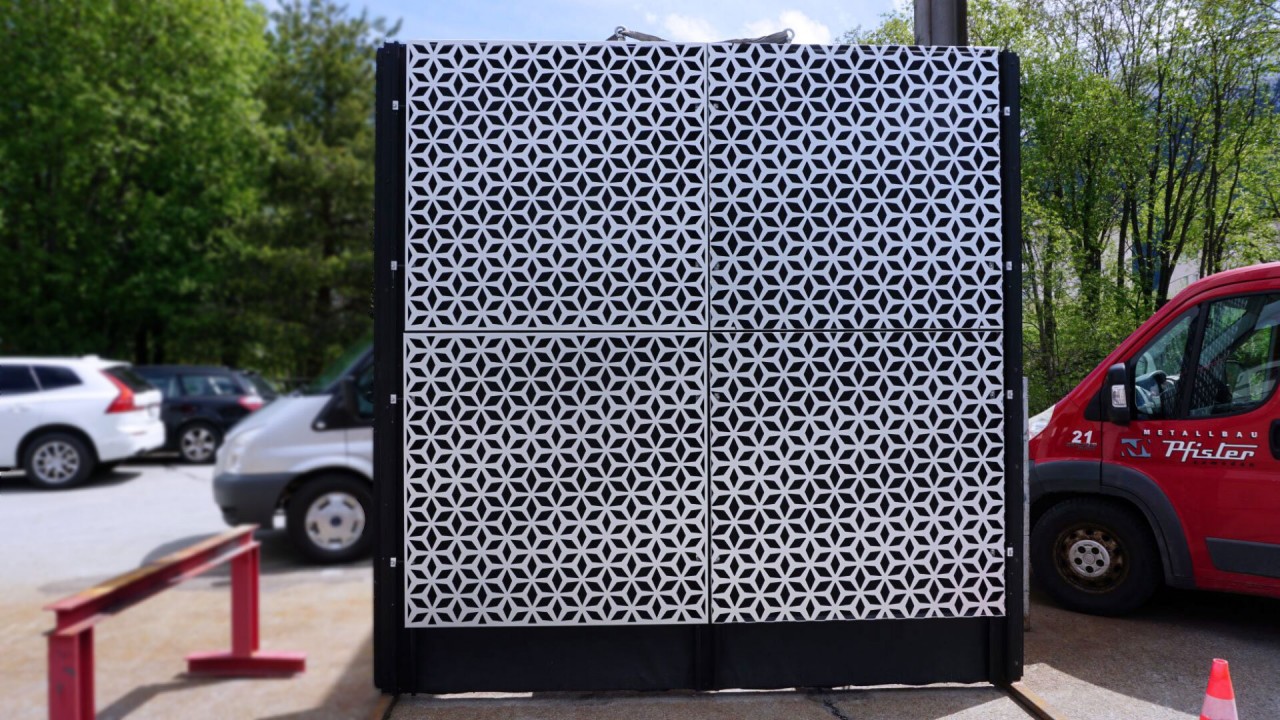

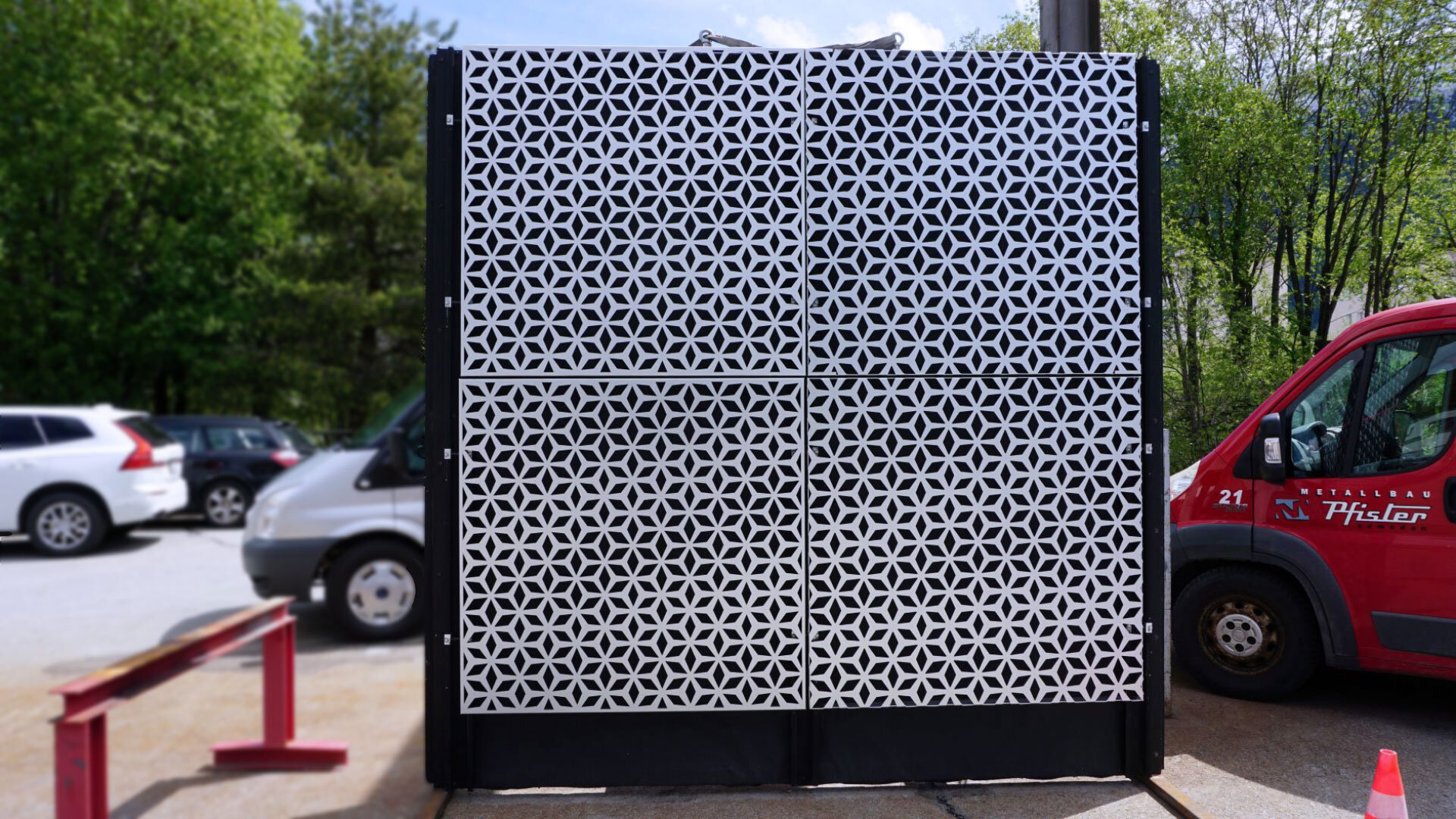

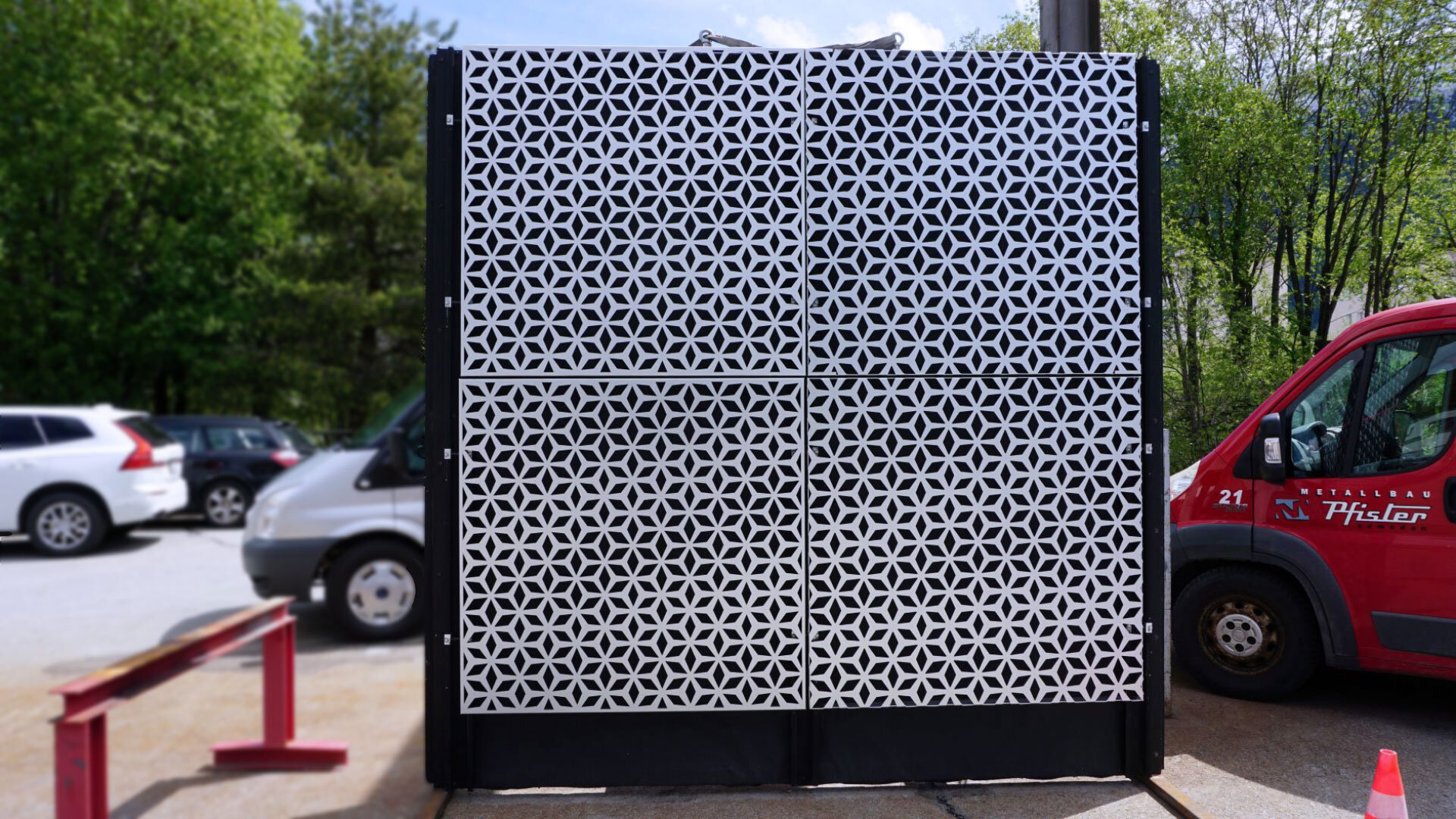

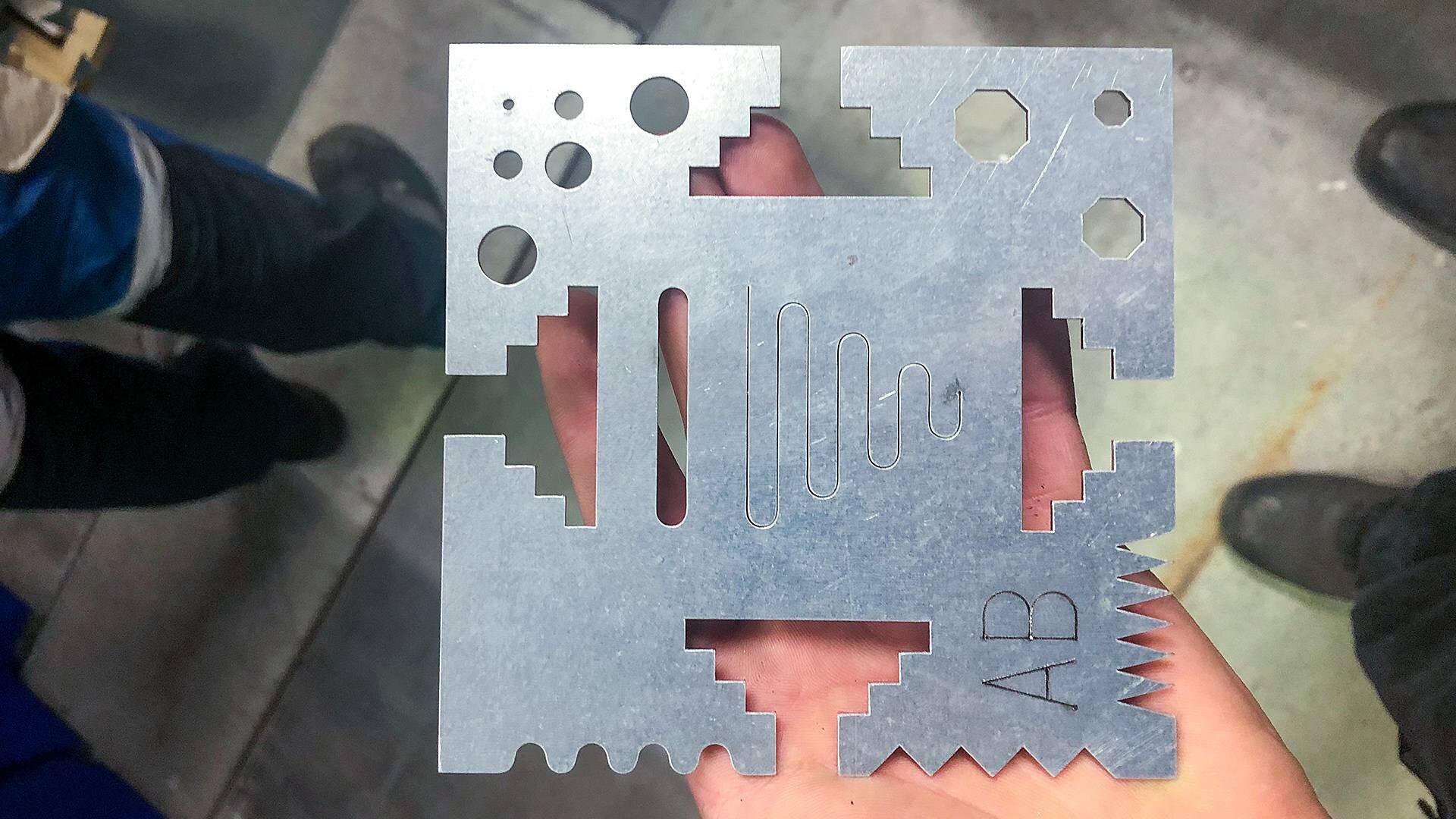

At the production start at the end of 2019, the investment is an important helper in a flagship project. 80% of its operation time, the machine was working on the façade of the Porta Samedan shopping center that opened in 2021 just a few minutes’ walk from the company headquarters. The outer façade cladding consists of 3 mm thin aluminum sheets, each cut with a fiber laser cutting machine of the latest generation. The overall view of the perforated pattern results in a wave pattern that refers to the water-rich area and changes its appearance according to ambient light.

A panel of the Porta Samedan shopping center façade. The outer façade cladding consists of 3 mm thin aluminum sheets cut with the new MSF Compact fiber laser cutting machine.

© Metallbau Pfister AG

Now it is mostly cutting connecting plates for beams from steel sheets 8, 10 and 12 mm thick. Thanks to its powerful 6 kW fiber laser source, it can cut steel up to 20 mm.

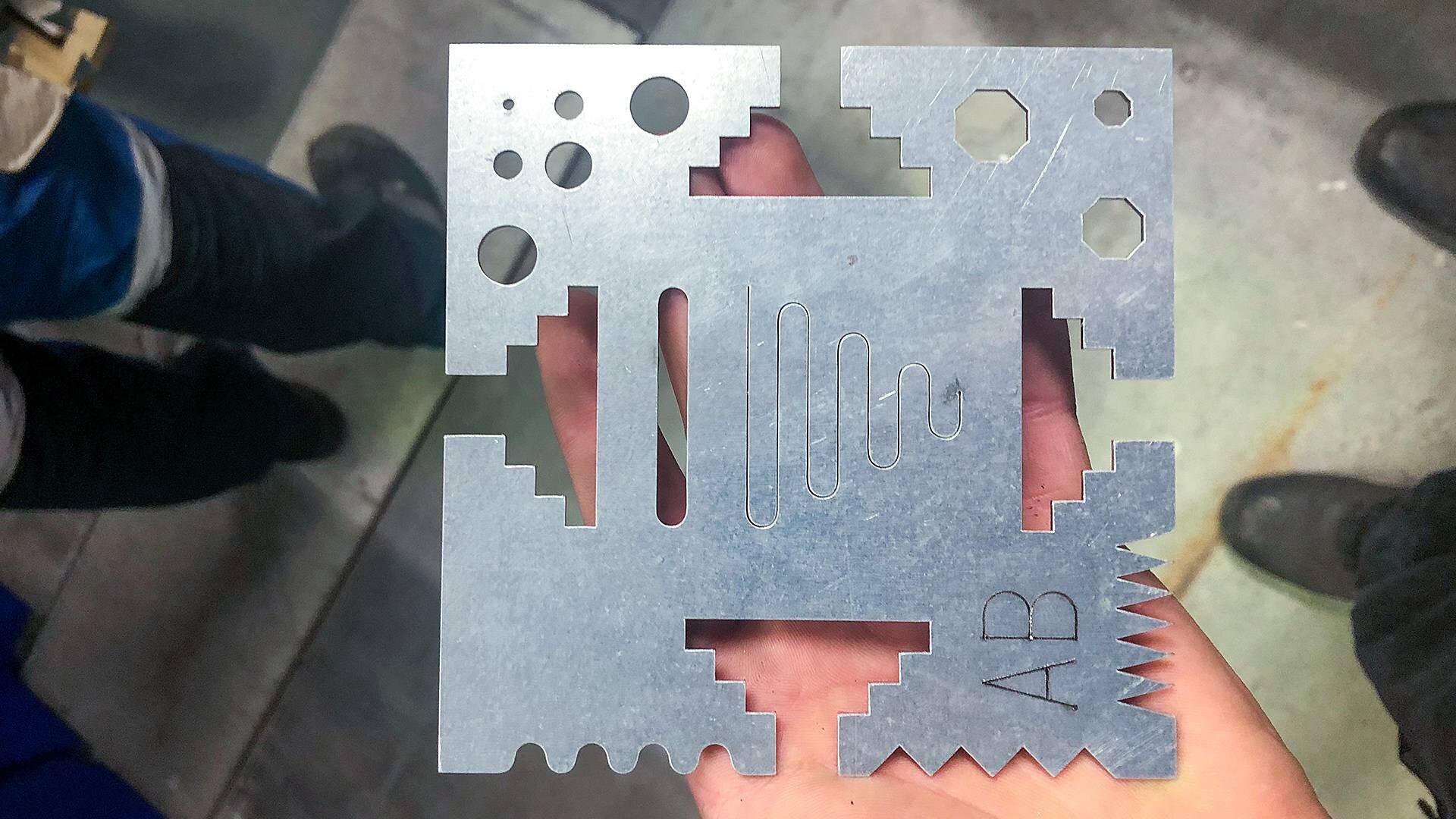

No more expensive laser partsThe decision to invest in a new laser cutting system was made after taking a close look at contract laser cutting costs, which were steadily rising. The existing plasma cutting machine - also from MicroStep - could not meet the changing and growing requirements anymore. “We were satisfied, it worked well, but it was no longer suitable for our requirements. We wanted a new machine that would meet our current needs in terms of precision and speed.” Following Pfisters' positive experience with MicroStep, Curdin and his father Urs, also a Managing Director, took a closer look at fiber lasers. Their plasma cutting machine had to be sold for space reasons; a larger CNC cutting system with laser technology and a shuttle table was also not an option. A live presentation of MSF Compact by MicroStep Europa made their decision. “It was very pleasant for us to go to Bad Wörishofen and take a look at the machine. We were able to cut our samples live, which further increased our confidence in the system.” Purchasing any additional parts is now hardly necessary.

“It was very pleasant for us to go to Bad Wörishofen and take a look at the machine. We were able to cut our samples live, which further increased our confidence in the system,” says Curdin Pfister.

Switching from the MicroStep’s plasma machine to the new fiber laser cutting machine also went smoothly: “We were able to rely on our existing knowledge but also ask many questions and learn a lot from the technicians during the installation. That helped us to be flexible."

For Curdin and his father Urs Pfister, the investment returned immediately. “This is exactly the machine we need here in the company for our work. It is small and compact and fits exactly into our limited space. The precision is very impressive,” says Urs Pfister.

Urs Pfister, Managing Director

© Metallbau Pfister AG