The history of

Ulrich Lippert GmbH & Co KG started in a workshop in Berlin shortly after the Second World War with the production of metal bell plates. 70 years later, Lippert focuses mainly on development, design, production and sale of sophisticated systems and solutions for building communication and building security. Many architects, contractors, housing companies as well as craftsmen trust their custom-made speech systems, access control solutions, letterboxes and building signage. Numerous projects, in Germany and throughout Europe, document the diversity of the company’s portfolio. Among other things, the company was involved projects like the tower of the European Central Bank in Frankfurt and the historic Cumberland building in Berlin.

“Our strength is that, despite serial production, we still manufacture orders very individually and use high-quality materials. We are still using a lot of manual processes with many high-precision operations required,” Rashid Sinayokho, Managing Director of Ulrich Lippert GmbH & Co KG explains. Individual approach and flexibility are two pillars on which the success of this group is based. To make this happen, the company’s 100 employees take advantage of their state-of-the-art technology equipment.

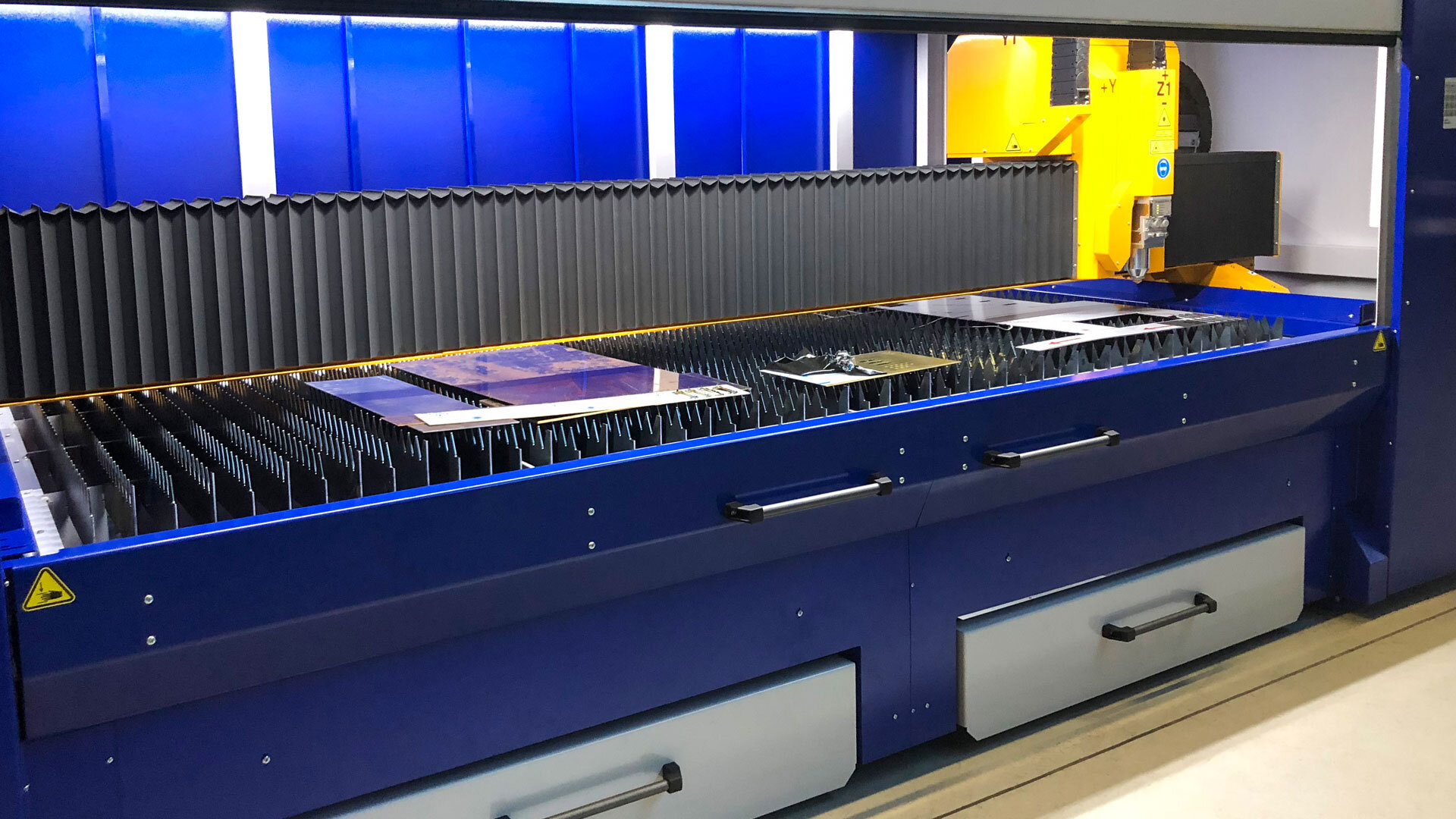

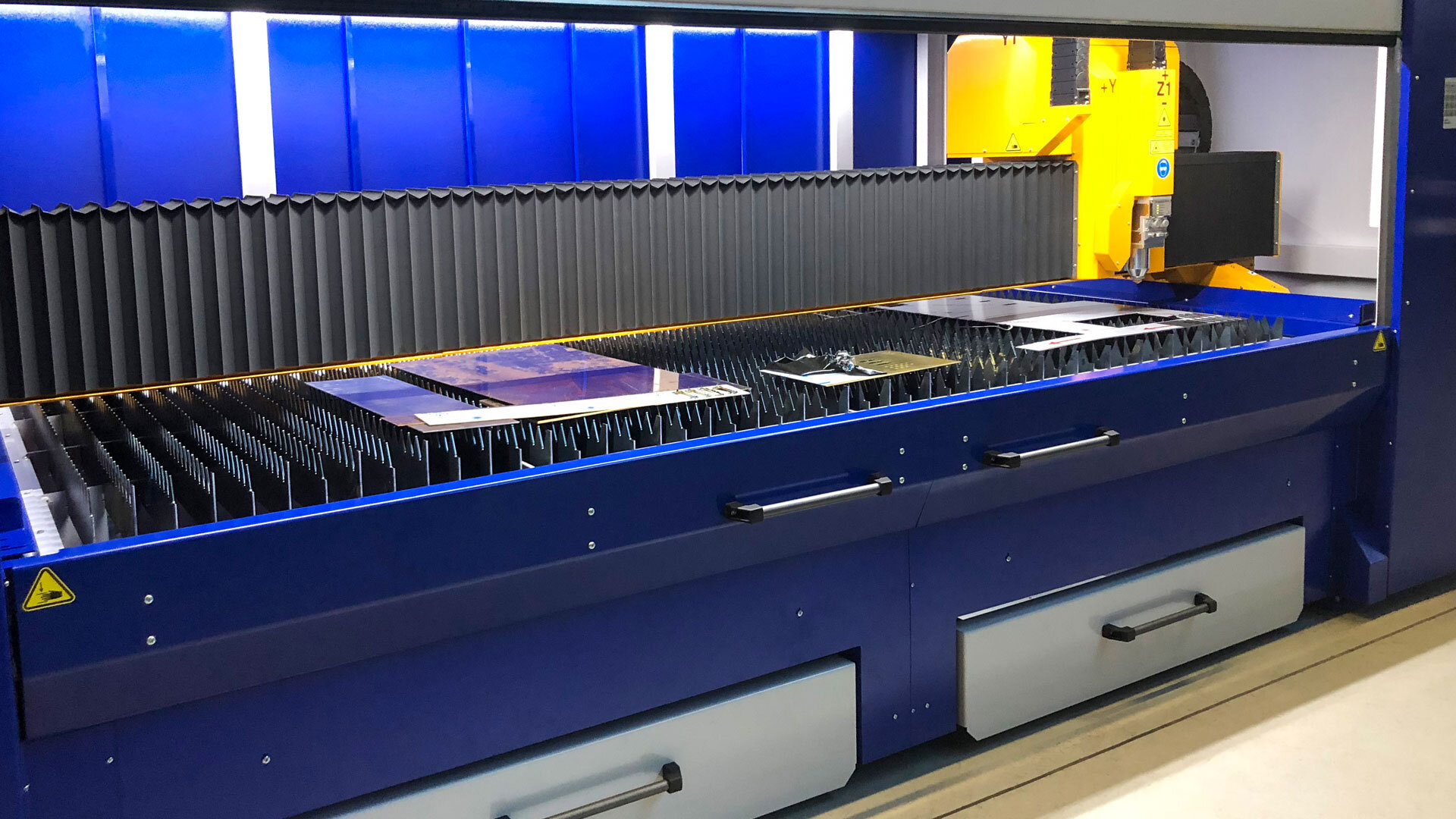

The company's final decision was in favor the MSF Compact, with a 2D cutting head and a working surface of 1 500 x 3 000 mm.

Looking to expand the machine park In 2018, Lippert was looking to supplement the company’s machine park with a new solution that would allow them to cut small batches from thin metal sheets. After perusing the market and examining various cutting technologies, their search for the ideal solution led the decision-making team to the

EuroBLECH industrial fair in Hannover. It was this fair where the fiber laser cutting machine

MSF Compact had its debut. Therefore, it was an ideal opportunity for Lippert to see it live and at work.

“It was a great consultation filled with patience and expertise and it convinced us to go for MicroStep. Even after our visit to the fair, all questions were answered patiently and many samples were made with our desired materials so that we were sure about our decision,” says the Managing Director. The final decision was in favor the MSF Compact, with a

2D cutting head and a working surface of 1 500 x 3 000 mm. It is an ideal choice for processing different those small and medium batch orders in mild steel, stainless steel, aluminum or brass between 0.8 to 5 mm thick that Lipert needs to cut most often.

MSF Compact is an ideal choice for processing small and medium batches in mild steel, stainless steel, aluminum or brass between 0.8 to 5 mm thick that Lipert needs to cut most often.

After intensive consultation, smooth delivery, commissioning and start of production, Mr. Sinayokho draws a thoroughly positive conclusion: “The support was really good, I could not have wished for more. The most important parameters in the decision process were the flexibility and cutting quality.”

“The machine is just right”“The customer gets exactly what he needs from us. The machine is just right. The most important parameters in choosing the right system were flexibility and cutting quality. And the system runs as we imagined,” reveals Mr. Sinayokho. Delivery, commissioning and training were on schedule. This was important, because the new machine has been put into a strict production plan for the factory. “The customer care is all I could wish for. When there is a problem then you take care of it, there is always someone present.”

„The machine runs as we imagined,” says Rashid Sinayokho, Managing Director of Ulrich Lippert GmbH & Co KG.