Ultra-Cut XT systems give you the flexibility to increase cutting power and the assurance of superior quality, higher productivity and lower cutting costs. Ultra-Cut-XT systems are available in 100-400 Amp outputs for cutting plate up to 50 mm thick. And because of its expansion capabilities, you never have to worry about choosing the right system.

Advanced Technology Solutions Set Thermal Dynamics Apart:

ScrapCutter

There’s no longer a need for an external manual plasma cutter or oxyfuel torch to cut the leftover metal skeleton into manageable pieces. Just connect the manual TD 1Torch® to the Ultra-Cut XT power source and start cutting.

- Consistent 100A output

- Torch length up to 30 m including extensions

- Fold back circuit (45A) if tip touches the plate (improves parts life)

- Rapid restart for constant arc on to improve cut times

- Activated by torch trigger only. No need to go back to XT power supply to switch the function on or off

StepUp™ Modular Power TechnologyThermal Dynamics designed the Ultra-Cut XT with the flexibility to grow with your business. It features modular “inverter blocks” and a common cabinet for all amperages.

To expand a 100A system into a 200A, 300A or 400A system, additional blocks can be easily installed. A field technician can install a new inverter block in less than 30 minutes.

The Thermal Dynamics intelligent approach means never “under-buying” again. With Ultra-Cut XT systems, you’ll always have the right amount of power today — and tomorrow.

Diameter PRO™ Technology

Diameter PRO™ TechnologyDiameter PRO is a software based intelligent solution that allows Ultra-Cut XT systems integrated with the Thermal Dynamics iCNC XT controller to optimise quality for holes with a diameter to thickness ratio of 1:1 or greater. It is the ideal process for a precision hole or radius with minimal-to-no taper on mild steel and aluminium from 3 mm to 25 mm.

- Diameter PRO automatically adjusts an infinite variety of settings – anything from cut speeds and torch heights to arc voltages and cut diameters.

- Integrated height control works seamlessly with the integrated drive system to control machine motion and cut high quality holes every time.

- Diameter PRO is compatible with any existing nesting software

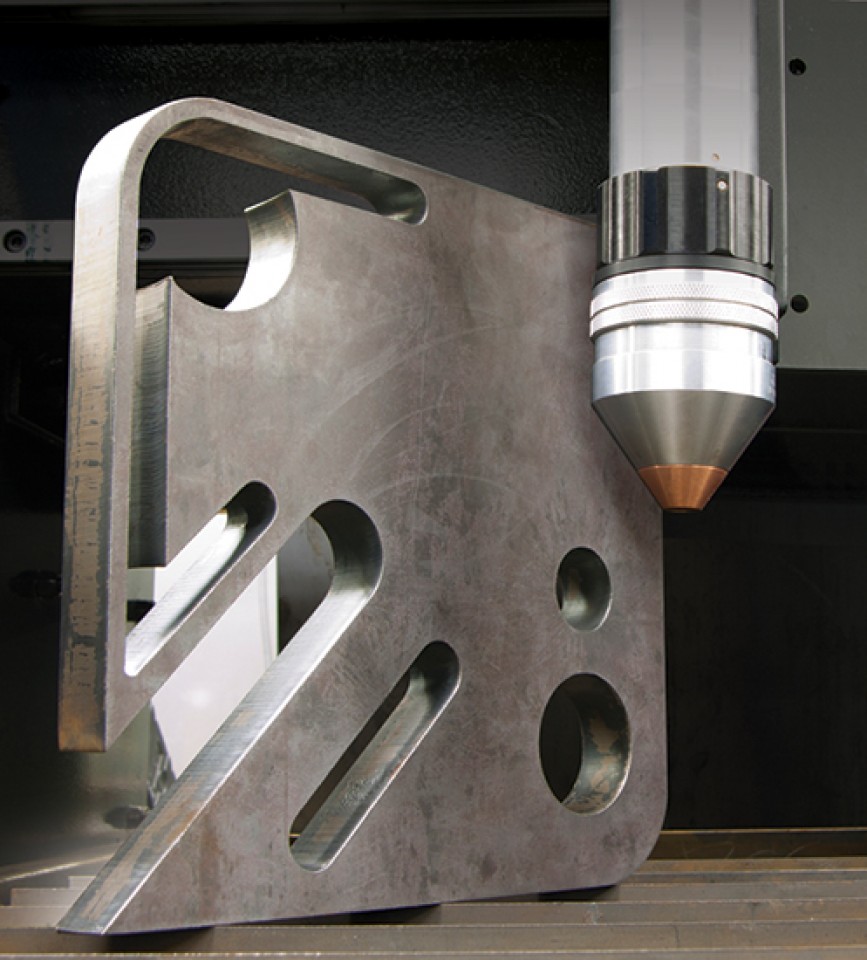

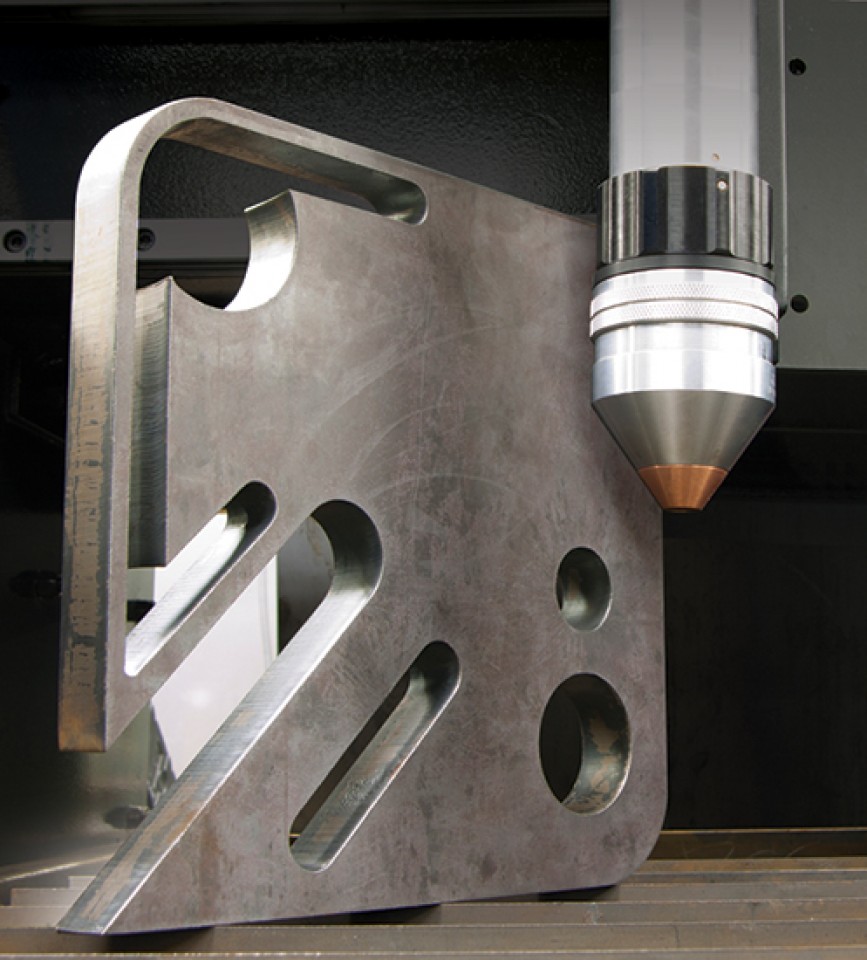

HeavyCut™ Technology

When cutting parts thicker than 20 mm, Ultra-Cut XT uses HeavyCut Technology to improve cutting efficiency and extend the useful life of the consumable parts. Advanced consumable parts and process parameters cut thicker plates better, last longer and result in lower cost per cut. True precision performance is no longer limited to thinner plates.

- 300 A and 400 A electrodes with multiple Hafnium inserts increase parts life to new levels at high current applications.

- Two-piece, high-amperage tip design directs coolant all the way to the orifice to ensure consistently high cut quality over the entire lifespan of the tip.

Watermist Secondary Technology (WMS®)

Ultra-Cut XT systems use WMS Technology to deliver excellent non-ferrous cut quality and low cost of operation by using N2 as plasma gas and ordinary tap water as the secondary. Gas costs are reduced, cut speed is increased, and distortion and the heat-affected zone are minimised. The result is a clean, dross- and oxide-free cut surface that’s ready to weld, form and paint. Water Mist Secondary reduces production costs and keeps overall energy usage to a minimum. Recommended for non-ferrous cutting up to 40 mm.

- Lowest operating cost.

- Cut speeds up to 3 times higher compared to H35 cutting.

- Dross-free cutting from 1 mm to 40 mm.

- Oxide-free cut face surface.

- Wide parameter window makes it easy to obtain the best results

- Operator-friendly

- Cut quality on aluminium is comparable to laser

- Small heat-affected zone and less distortion

- Cut surface is ready to weld